The evolution of packaging materials has been a journey defined by innovation and adaptation. In the early days, paper, glass, and metal were the primary materials used for protecting and preserving products. While these materials provided adequate protection, they came with several limitations such as weight, cost, and limited barrier properties against moisture and gases.

With the advent of plastic films, the packaging industry witnessed a revolutionary shift. Initially, various kinds of plastics were introduced into the market, but it was the development of polyethylene and polypropylene that significantly altered packaging dynamics. Over time, Cast Polypropylene (CPP) film emerged as a preferred material due to its versatile application potential and enhanced properties. Technological advancements have further refined CPP film production, making it an indispensable component in modern packaging solutions.

Key Properties of CPP Film

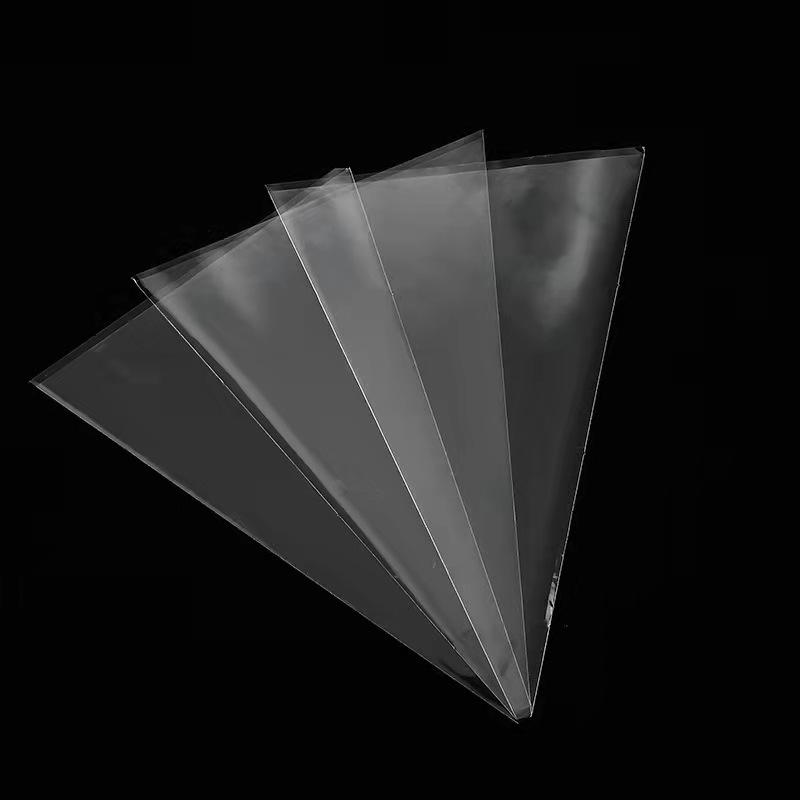

At its core, CPP film is composed of polypropylene, a polymer known for its robustness and resistance to chemical and physical stress. Compared to Biaxially Oriented Polypropylene (BOPP), which is stretched in two directions for added strength, CPP film offers higher flexibility and excellent clarity while maintaining good strength and durability. Additionally, CPP exhibits superior barrier properties against moisture and gases, ensuring better product preservation.

One of the critical advantages of CPP film lies in its environmental impact. Unlike some plastic alternatives, CPP film is recyclable, contributing to more sustainable packaging cycles. It also aligns favorably when compared to other plastic films regarding environmental footprint, offering a balanced approach between performance and eco-friendliness.

Usage Scenarios in Packaging

In food packaging, CPP film is widely utilized for wrapping fresh produce, bakery items, and snacks. The film's barrier properties help maintain food freshness and safety, extending shelf life and reducing waste. For instance, manufacturers use CPP film to preserve the crunchiness of snacks or keep bakery items soft and moist.

The pharmaceuticals and medical device industries benefit immensely from the sterility and protective qualities of CPP film. Its application in blister packs and other medical packaging ensures that products remain uncontaminated, safeguarding both efficacy and patient health.

Additionally, CPP film finds extensive applications in consumer goods packaging, including electronics, textiles, and household items. It enhances product presentation through its inherent clarity and gloss, making packaged goods more visually appealing. Furthermore, the film provides robust protection during transit and storage, reducing damage rates and associated costs.

Benefits of Using CPP Film

A significant benefit of using CPP film is its capability to improve shelf life. By effectively blocking moisture and gases, CPP film keeps perishable goods fresher for longer periods, directly impacting consumer satisfaction and reducing inventory losses.

The material’s enhanced appearance and printability set it apart in the cluttered marketplace. With high clarity and gloss, CPP film offers clear visibility, thereby boosting product attractiveness. It is compatible with various printing techniques, allowing brands to incorporate intricate designs and vibrant colors on their packaging, facilitating better brand recognition.

Cost efficiency is another key advantage. Despite the advanced properties of CPP film, the production costs are relatively lower than many alternative materials. This balance translates into long-term savings for both manufacturers and retailers, promoting economic viability alongside functionality.

Technological Innovations and Advancements

The field of CPP film technology continues to evolve with groundbreaking innovations. One area experiencing rapid development is nanoengineering, enabling even thinner yet stronger films. Multilayer co-extrusion techniques have also allowed the creation of customizable films tailored for specific barrier needs. Smart packaging solutions represent another innovative frontier. Integrating technologies like RFID and QR codes within CPP films offers new dimensions of traceability and consumer interaction. Temperature-sensitive and self-healing films are recent advancements poised to revolutionize how we think about packaging resilience and adaptiveness.

Case Studies and Real-World Applications

Several notable success stories underscore the benefits of adopting CPP film in diverse sectors. Leading food brands, for example, have reported extended shelf lives and reduced spoilage rates, translating directly into financial gains and improved customer satisfaction. Similarly, healthcare companies deploying CPP-based sterile packaging achieve greater adherence to safety standards. Although challenges occasionally arise, such as specialized machinery requirements for processing CPP film, ongoing innovations continue to address and mitigate these issues, streamlining implementation across different industries.

Future Trends in CPP Film Packaging

The future of CPP film packaging appears promising, especially concerning sustainability initiatives. There is a growing trend towards biodegradable and compostable films, aligning with global efforts to reduce plastic waste. Industry standards and regulations are constantly evolving to foster greener practices without compromising performance. Market growth projections indicate increasing demand for CPP film across various sectors, driven largely by emerging markets recognizing its value proposition. Ongoing research underscores this trajectory, continually refining our understanding and capabilities of CPP film technology.

Expert Opinions and Industry Insights

Leading voices in the packaging domain, including engineers and designers, emphasize the transformative potential of CPP film. Their perspectives offer invaluable insights into impending developments, reinforcing its relevance and adaptability. Current research findings corroborate practical observations, highlighting enhancements in CPP film properties and exploring its widening applicability. As consumer preferences increasingly gravitate towards quality and sustainability, CPP film stands as a resilient and forward-looking solution in modern packaging strategies.