When it comes to cold storage packaging, CPP (Cast Polypropylene) films emerge as a groundbreaking solution that meets various industry requirements efficiently. But what exactly are CPP films? Composed primarily of polypropylene, these films are made through a casting process that results in a versatile material with numerous benefits.

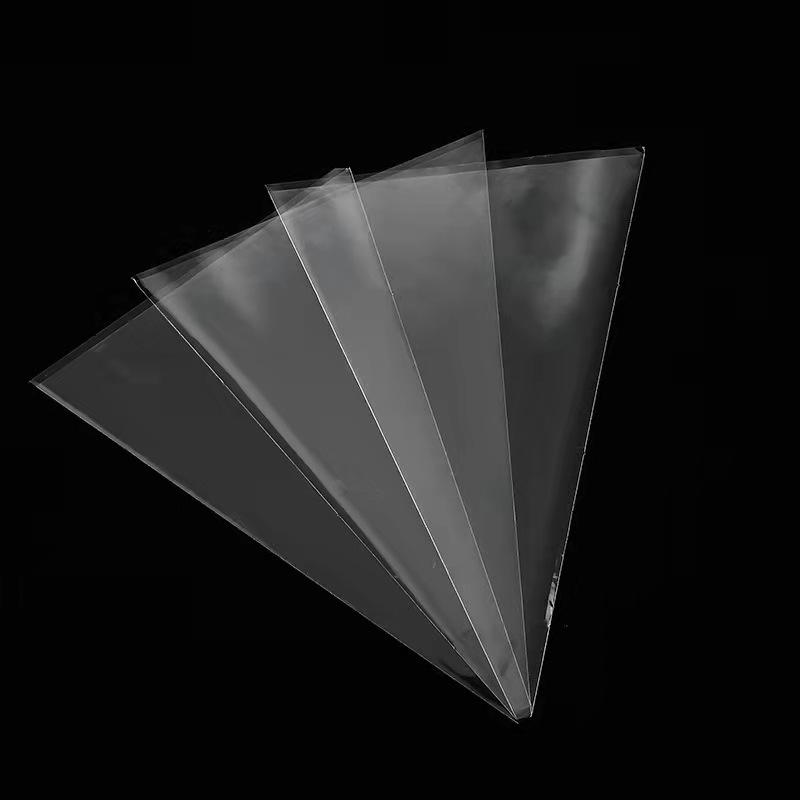

One of the key characteristics of CPP films is their excellent transparency, which enhances product visibility—crucial for consumer appeal. They also provide outstanding sealing performance and flexibility, making them an ideal choice for diverse packaging needs.

The increasing importance of cold storage packaging cannot be overstated. It requires materials that can withstand low temperatures while maintaining structural integrity. Conventional options like polyethylene and polyvinyl chloride may not always offer optimal performance under such conditions. However, CPP films excel by providing superior temperature tolerance and resistance to cracking or brittleness, overriding many of the limitations posed by other materials.

A major advantage of CPP films lies in their cold-resistant properties. These films have impressive temperature tolerance ranges and maintain their functional efficiency even when exposed to extremely low temperatures. The inherent barrier properties against moisture and oxygen make them particularly effective for extending the shelf life of perishable goods.

To illustrate their effectiveness, consider the frozen food industry—a sector heavily reliant on robust packaging solutions. CPP films consistently demonstrate exceptional performance in extreme cold conditions. Multiple case studies show how leading brands utilize CPP films to ensure their products stay fresh and intact during transport and storage. Compared to traditional packaging methods, CPP films offer better security against freezer burn and dehydration.

For chilled products stored within refrigerated environments, CPP films again shine brightly. Their suitability for chilled storage helps maintain product freshness and quality, crucial elements for dairy products and beverages. These industries often employ CPP-based solutions due to the films' ability to keep items hygienic and visually appealing while preventing spoilage.

An additional layer of attraction towards CPP films is their eco-friendliness. With growing concerns over environmental impact, the recyclability of CPP films adds to their allure. Innovations in sustainable production practices continually evolve, further solidifying the ecological advantages of adopting these films.

Manufacturers will find several practical considerations beneficial when incorporating CPP films into their workflow. Cost-effectiveness remains a significant draw, allowing businesses to protect their margins without compromising on packaging quality. Moreover, customization options cater to specific needs, ensuring regulatory compliance and safety standards are met across different regions and sectors.

Looking toward the future, advancements in technology promise exciting developments in the field of CPP film production. Emerging technologies aim at boosting the already commendable cold storage performance of these films. Industry predictions highlight sustained market growth driven by continuous improvement and adaptation to new challenges and opportunities.

Leading brands give credence to the efficacy of CPP films through real-world applications and testimonials. Success stories abound from various corners of the globe where companies report enhanced customer satisfaction and operational efficiency due to switching to CPP films. Packaging experts and consumers alike express high regard for the benefits these films bring to the table.

In closing, CPP films present myriad advantages for cold storage packaging. From astonishing cold resistance to remarkable sustainability, they meet modern-day demands comprehensively. As we venture into the next phase of packaging innovation, CPP films are poised to play an indispensable role, heralding a brighter, more efficient future in cold storage solutions.