Exploring Composite Films

Composite films are multilayered materials obtained by combining different polymers and additives to create a product that exhibits superior characteristics compared to single-layer films. This combination leads to enhanced strength, flexibility, durability, and barrier properties essential for modern packaging needs.

The importance of composite films in today's packaging industry cannot be overstated. They provide improved protection against moisture, gases, light, and physical damage, extending the shelf life of products and maintaining their quality during transport and storage.

Construction of Composite Films

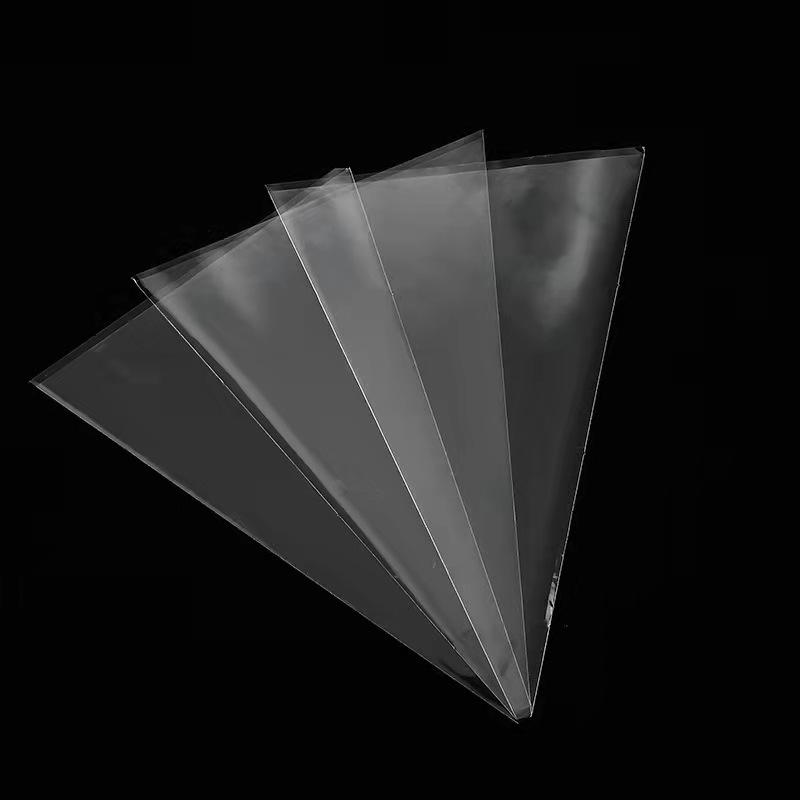

The construction of composite films involves carefully selecting and combining various layers, each designed to fulfill specific roles. Commonly used primary materials include polyethylene, polypropylene, BOPP (Biaxially Oriented Polypropylene), and CPP (Cast Polypropylene). Each layer's material contributes unique attributes like strength, clarity, or resistance to environmental factors.

Bonding these layers together is crucial for composite film integrity. Techniques like extrusion coating and lamination are employed; extrusion coating involves applying a molten resin onto a substrate, while lamination entails bonding multiple layers using adhesives or heat.

Key Properties of Composite Films

One of the most notable qualities of composite films is their durability. These films can withstand mechanical stresses, protecting contents from damage. Flexibility ensures they can wrap around complex shapes without tearing or losing integrity.

Barrier properties are vital for preventing gas and moisture permeation, which is critical in preserving the freshness and safety of food and pharmaceuticals. Furthermore, composite films offer remarkable thermal resistance, making them suitable for various temperature ranges encountered during processing and usage.

Applications in Various Industries

In the food and beverage sector, composite films play a pivotal role in enhancing product shelf life by ensuring optimal moisture levels and protecting against contaminants. For instance, snack packs often utilize such films to maintain crispiness over time.

The pharmaceutical industry benefits significantly from composite films, as they prevent contamination and preserve drug efficacy through excellent barrier properties. Blister packs for tablets commonly use these films to ensure drugs remain uncontaminated and effective.

Industrial applications utilize composite films as protective coverings for machinery and tools due to their robust nature and ability to resist harsh environmental conditions. The automotive and electronics sectors also employ these materials for safeguarding components.

Advantages Over Traditional Packaging Materials

Compared to traditional packaging solutions, composite films offer enhanced strength and durability, reducing the risk of product loss or damage. Their lightweight nature translates to lower transportation costs and a smaller carbon footprint.

Moreover, composite films are highly customizable, allowing manufacturers to tailor them according to specific needs—whether it’s adding UV resistance, printability, or special finishes.

Environmental Impact and Sustainability

As the world grapples with sustainability challenges, innovations within composite films are enabling biodegradable options that minimize environmental impact. While recycling composite films poses difficulties due to their multi-material composition, advancements are being made in separation techniques and design-for-recycling concepts.

Pioneering eco-friendly materials, such as bio-based plastics, contribute toward more sustainable composite films, balancing performance requirements with ecological considerations.

Case Studies and Real-World Examples

Many leading brands have adopted composite films across diverse sectors. Notably, food giants use them to maintain product quality and extend shelf life. Performance metrics have shown significant reduction in spoilage rates and increased customer satisfaction due to better-preserved products.

Pharmaceutical companies report fewer instances of medication degradation, directly impacting public health positively. Such case studies underscore the reliability and effectiveness of composite films in real-world settings.

Future Trends and Innovations

Technological advancements are continually pushing the boundaries of composite film capabilities. Enhanced manufacturing processes and novel material formulations are resulting in films with even greater functionality and applicability.

The composite film market shows robust growth projections, driven by escalating demand across industries. Emerging trends suggest an integration of smart technologies into films, such as embedding sensors for tracking freshness and authenticity.

Tips for Choosing the Right Composite Film

Selecting the appropriate composite film necessitates a thorough assessment of specific packaging needs. Factors like product type, storage conditions, and required shelf life should guide decisions.

A cost-benefit analysis will help balance between desired features and budget constraints, while evaluating potential suppliers based on expertise, reliability, and compliance with industry standards ensures quality and consistency.

Final Thoughts on Composite Films

Composite films have revolutionized modern packaging by addressing various practical challenges efficiently. From extended shelf lives to customization possibilities, the benefits are compelling. Ongoing innovation promises further enhancements, securing their relevance well into the future.

Their long-term viability in the packaging industry makes composite films an indispensable tool for businesses aiming to optimize product preservation, reduce waste, and meet evolving consumer demands sustainably. As technological advances continue, the scope and capabilities of composite films will only expand, cementing their position as a crucial component in advanced packaging solutions.