Shrink film technology has come a long way since its first introduction as a packaging solution. Initially used for basic product containment, it has evolved remarkably due to technological advancements. This journey from traditional forms to the modern innovations we see today epitomizes an ongoing commitment to improving product preservation, aesthetic appeal, and environmental impact.

A Glimpse into Shrink Film Innovation

The evolution of shrink film technologies showcases several key milestones that have shaped the industry. Early shrink films primarily focused on functionality but offered limited flexibility in terms of application or material composition. Over time, crucial developments such as the creation of cross-linked polymers and multi-layered films have paved the way for more adaptable, durable, and proficient solutions. These advancements also underline the pivotal role of innovative thinking and sophisticated engineering in revolutionizing the packaging sector.

Cutting-Edge Materials and Compositions

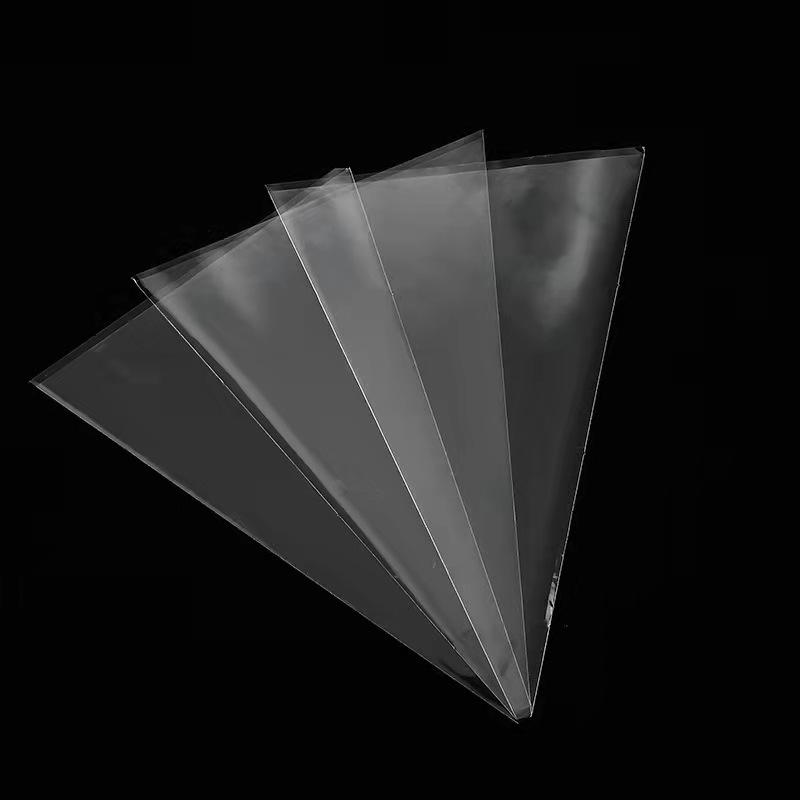

Modern shrink films benefit significantly from the use of advanced polymers like biaxially oriented polypropylene (BOPP) and cast polypropylene (CPP). These materials offer superior performance compared to their conventional counterparts. For example, they provide better strength-to-weight ratios, making them both robust and lightweight. Additionally, these newer compositions present improved clarity, ensuring enhanced visual presentation for packaged products.

Another critical consideration is sustainability. The shift towards eco-friendly materials, including those that require fewer resources during production and generate less waste post-consumption, illustrates an industry-wide move to reduce environmental footprints. Companies like Wang Qingxiang Plastic Business are leading the charge by offering a diverse range of sustainable shrink films tailored to meet varying needs without compromising quality.

Advanced Manufacturing Processes

The manufacturing process of shrink films has been fine-tuned through state-of-the-art extrusion techniques. Precision in temperature control and film formation ensures consistent quality and minimal defect rates. Moreover, automated systems enhance efficiency by streamlining production lines, reducing human error, and optimizing resource utilization.

This automation not only boosts productivity but also facilitates scalability, allowing manufacturers to meet increasing demands without substantial delays or escalated costs.

Enhanced Functional Properties

Today's shrink films boast several functional properties that set them apart from earlier versions. Improved strength and durability protect goods better during transportation and handling, while superior clarity enhances product visibility, making items more appealing to consumers.

Additionally, robust barrier properties ensure protection against moisture, oxygen, and other contaminants, thus extending shelf life and maintaining product integrity. Such attributes are particularly vital for perishable goods, pharmaceuticals, and sensitive electronics components.

Diverse Applications in Various Industries

Shrink film's versatility allows its usage across multiple industries. In food and beverage packaging, it secures freshness and prevents contamination. Pharmaceutical and medical applications leverage its robust sealing capabilities to safeguard medicines and equipment. Meanwhile, electronics and consumer goods benefit from its protective yet transparent covering, which deters tampering and damage without hiding packaged contents.

Market Impact and Economic Benefits

The adoption of new shrink film technologies translates to significant economic benefits. Enhanced production efficiencies and optimized resource use lead to cost savings, while the reduction in packaging waste supports environmental goals. Businesses utilizing these advanced solutions gain competitive advantages through better-quality packaging that can improve brand perception and customer satisfaction.

Challenges and Future Outlook

Despite these advancements, the industry faces challenges such as technical limitations and compliance with stringent regulations. Innovators continuously strive to overcome these hurdles, pushing boundaries to achieve even higher standards. Looking ahead, trends indicate further development in bio-based materials and smart films equipped with sensors for real-time condition monitoring.

Case Studies and Real-World Examples

Several leading companies have successfully integrated advanced shrink film technologies into their operations. For instance, businesses report quantifiable improvements in product durability and reduced spoilage rates. Industry experts endorse these innovations, highlighting measurable benefits and positive feedback from end-users who appreciate the elevated packaging quality.

Guidelines for Adoption and Implementation

For organizations considering the switch to modern shrink film technologies, a strategic approach is essential. Key steps include evaluating current packaging needs, investing in employee training for new systems, and partnering with reliable technology providers. Such measures ensure a smooth transition and maximize the return on investment.

Interactive and Multimedia Content

Engaging multimedia elements can elucidate the complexities of shrink film technologies. Infographics display technological improvements vividly, while video demonstrations offer insights into sophisticated manufacturing processes. Expert interviews and panel discussions provide deeper understanding and foster conversations around best practices and future directions.

Engaging with the Community

We invite readers to share their experiences and insights about shrink film technologies. A Q&A section can address related queries, and links to additional resources will help deepen your knowledge. Join us in exploring and implementing these transformative packaging solutions.